Figure: IGT-based NAND and NOR gates conform to the surface of orchid petals (left). Scale bar, 1cm. Optical micrographs of NOR (upper right) and NAND (lower right) logic gates. Input (I1, I2) and output (O) configuration is indicated. Scale bar, 100 µm.

Our challenge

Current transistors do not have all the features required for safe, reliable operation in physiologic environments, like the human body, over extended periods of time. We aim to design and develop transistors that fulfil all these requirements and enable construction of safer, smaller, and smarter bioelectronic devices.

We would like to design and develop novel transistor architecture as a universal building block for integrated bioelectronic devices. These are devices that can interface with body monitor, process and intervene with physiological activity such as brain or muscles. Although a wide range of transistor architectures and materials is available, none incorporate all of the required features for a safe and reliable architecture.

Key features required for safe, efficient, and prolonged use of transistors in biological environments include: i) they should be made out of materials that are biocompatible and stable; ii) they should be soft and flexible to not cause tissue damage and discomfort; iii) they should allow high speed and amplification to detect potentially low-amplitude ionic signals of the body; iv) they should be able to be addressed independently and made in high resolution.

We developed a transistor that can incorporate all of these features together.

Our approach

In the past, traditional silicon based transistors were used in bioelectronic devices, but they have to be carefully encapsulated to avoid contact with body fluids – both for the safety of the patient and the proper operation of the device. This makes implants based on these transistors bulky and rigid.

In parallel, a lot of work has been done in the field of organic electronics to create inherently flexible transistors out of plastic. In fact, there are designs such as electrolyte-gated or electrochemical transistors that can modulate their output based on ionic currents. However, these devices cannot operate fast enough to perform the computations required for bioelectronic devices used in neurophysiology applications.

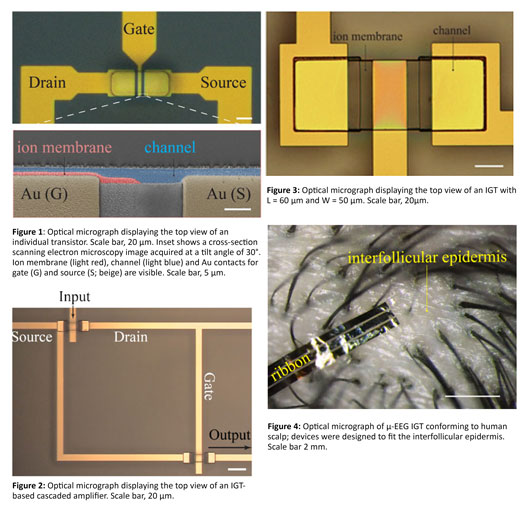

In this work, we designed our transistor channel based on conducting polymers to enable ionic modulation and to make the device fast we modified the material to have its own mobile ions. This way the distance ions are required to travel is shortened to within the polymer structure. This improved the speed of the transistor by an order of magnitude compared to other ionic devices with the same size. Importantly, we only used completely biocompatible material to create this device. Our secret ingredient is sugar! Sugar molecules help the transistor channel to stay hydrated and make the travelling of the ions easier and faster.

Our results

- We created a transistor that is made out of fully biocompatible materials.

- It can interact with both ions and electrons, making communication with neural signals of the body more efficient.

- We can use these transistors in combination to perform computations – like logic gates.

- We used our transistor to record human brain waves (EEG) from the surface of the scalp. The transistor was easy to apply to the scalp and did not cause any irritation. It was much smaller than any other EEG electrodes, making it possible to fit between human hairs, improving the application process and the signals that can be recorded.

Applications, how our results will impact the world

- We made soft and conformable devices for recording neural signals – this could significantly improve the ease and tolerability of EEG procedures for patients.

- These devices could also be used to make implantable closed loop devices, such as those currently used to treat some forms of medically refractory epilepsy; devices could be smaller and easier to implant, and also provide more information.

Significance of the findings

On the physical level, we are very excited that we could substantially improve ionic transistors by adding simple ingredients. With such speed and amplification, combined with their ease of microfabrication, these transistors could be applicable to many different types of devices. We are excited also about the potential to use these devices to benefit patient care in the future.

Significance of HFSP funding

The HFSP funding was of great significance for this research project. The main idea behind this research was first proposed in my application for the Cross-Disciplinary Fellowship back in 2016, the funding enabled me to join Prof. Khodagholy’s lab and the birth of this research. Lastly, the fact that the number of coauthors is limited to three, with two coauthors being principal investigators (Prof. Khodagholy, Prof. Gelinas) highlights the importance of each contribution and the role of HFSP funding.