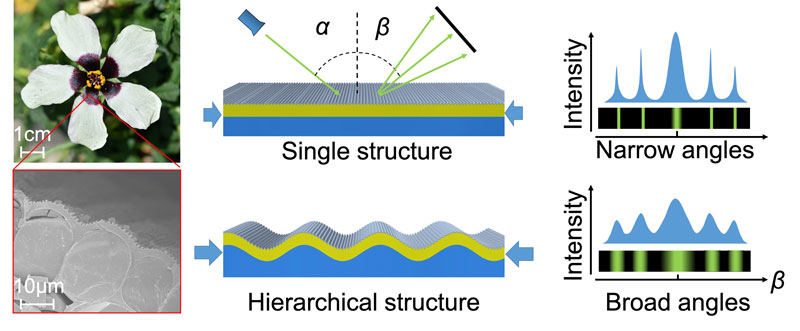

Some flower petals, such as those of Hibiscus trionum, display broad-angle structural colours in addition to pigment-based colours. The broad-angle attribute allows the diffraction-based, or structural, colour to be viewed from a larger span of vantage points, compared to more-traditional engineered diffracting surfaces. This unique iridescent spectrum has been shown to enhance the foraging efficiency of pollinators. Although previous efforts have mimicked the surface shape to recreate this broad-angle structural colour, the intrinsic tunability offered by natural systems to control such a broadened spectrum has not been demonstrated in synthetic models until now.

Figure: left to right: A Hibiscus trionum flower and the iridescent proximal part’s hierarchical surface structures. Schematic representation of the inspired mechanism for tuning structural colour across a broad range of observable angles. When the surface contains a single diffractive periodic grating, the diffraction angles are discrete with narrow bands. When the surface contains a hierarchical structure with two periodicities the small structure is diffractive, and the large structure broadens the diffraction angles.

In a study recently published in the journal Advanced Functional Materials, an HFSP research team from the University of Massachusetts Amherst and the University of Cambridge developed a precisely-defined multilayer composite, which formed a hierarchically wrinkled surface, with nanoscale wrinkles decorating larger sub-mm scale wrinkles. This combination of dual wavelength wrinkles only forms under certain conditions and is the key to providing structural colour across a broad range of observable angles.

This engineered system mimics not only the natural system’s performance but also its developmental mechanism. Multilayer wrinkling, which is the mechanism responsible for the features found on flower petals, offers a robust platform for engineering the biomimetic structures. As revealed in a quantitative model, the development of such broad-angle structural colour can only be achieved with an appropriate combination of material properties and geometric parameters. By combining experimental discovery, numerical and analytical modelling, and experimental validation, new quantitative guidelines are provided to guide the selection of materials and conditions for photonic devices with precise tuning capabilities.

This study has also helped to identify the limits for natural systems to allow for hierarchical wrinkling on petals, contributing to framing future work to identify factors that may disrupt natural wrinkling in plants.

This work is fully funded by HFSP - researchers from multiple disciplines across mechanical engineering, materials science, plant science, and physics were necessary to initiate and conduct this research.